Views: 172

Tarpaulin tearing strength by the trouser tear method

1. Scope

This standard specifies a method of determining the tarpaulin tearing strength under specified conditions. It is applicable to products that, because of their flexibility, do not tear when clamped between the grips of a tensile testing machine. The method makes it possible to compare samples of different products provided their thickness does not differ by more than 10%.

2. Normative references

This standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text, and the titles of the publications are listed below. For dated references, subsequent amendments to or revisions of any of these publications apply to this standard only when incorporated in it by amendment or revision. For undated references, the latest edition of the publication referred to applies.

| DIN 51220 | General requirements for materials testing machines, including verification and calibra- tion |

| DIN 53370

DIN 53515 |

Determining plastic film and sheeting thickness by the stylus method

Determination of tear strength of rubber and plastic film by Graves angle testing with cuts |

| DIN EN ISO 291

DIN EN ISO 527-1 |

Plastics – Standard atmospheres for conditioning and testing (ISO 291 : 1997)

Plastics – Determination of tensile properties – Part 1: General principles (ISO 527-1 : 1993 + Corr 1 : 1994) |

| DIN EN ISO 7500-1 | Metallic materials – Verification of static uniaxial testing machines – Part 1: Tension/com- pression testing machines – Verification and calibration of the force-measuring system (ISO 7500-1 : 1999) |

3. Concept

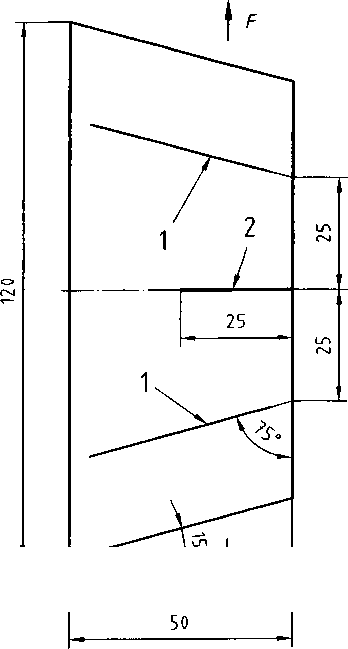

Tear resistance

Ratio of the force with which a trapezoidal trouser-shaped specimen as shown in figure 1 resists tear, to the specimen thickness.

Figure 1: Template

Figure 1: Template

Key

- Grip clamping marks

- Incision

4. Specimens

4.1 Sampling and specimen preparation

Specimens as shown in figure 1 shall be cut from the product to be tested. If possible, they shall be taken pap allel and transverse to the manufacturing direction (machine direction) of the film or sheeting so as to permit determination of the tear resistance in both directions as defined by the direction of the incision.

NOTE: If only one piece of the product is available and its manufacturing direction cannot be determined, specimens are to be taken in two directions normal to each other.

The cut directions shall be marked.

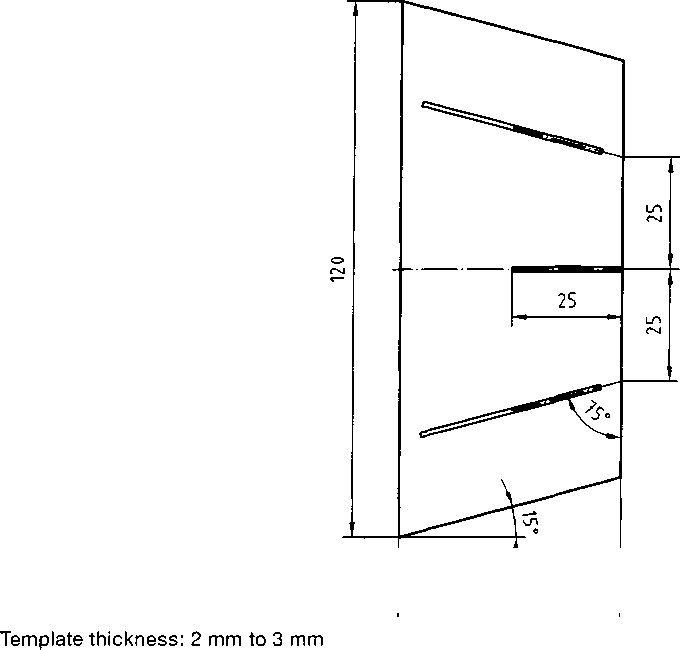

The use of a template as shown in figure 2, made of a cut-resistant material, will make it easier to cut out the specimen and make the incision with a knife or razor blade, and to make the grip clamping marks using a pen cil, ballpoint pen or grease pencil.

Figure 2: Template

4.2 Number of specimens

A minimum of five specimens shall be tested. If specimens are to tested in both directions, at least five shall be taken for each direction. In arbitration cases, at least ten specimens in each direction are to be tested.

5. Apparatus

5.1 Tensile testing machine

Class 1, as in DIN EN ISO 7500-1, conforming to the requirements of DIN 51220 and fitted with a device for gripping the specimen at the marks (see figure 1).

5.2 Measuring device

For measuring the specimen thickness as in DIN 53370.

6. Procedure

Carry out the tear test in a 23/50 standard atmosphere as in DIN EN ISO 291.

NOTE: In many cases, additional tests performed at lower and higher temperatures are recommended. For this purpose, an environmental test chamber shall be used during testing, capable of maintaining the required temperature to within 0.5 °C