Description

Views: 1181

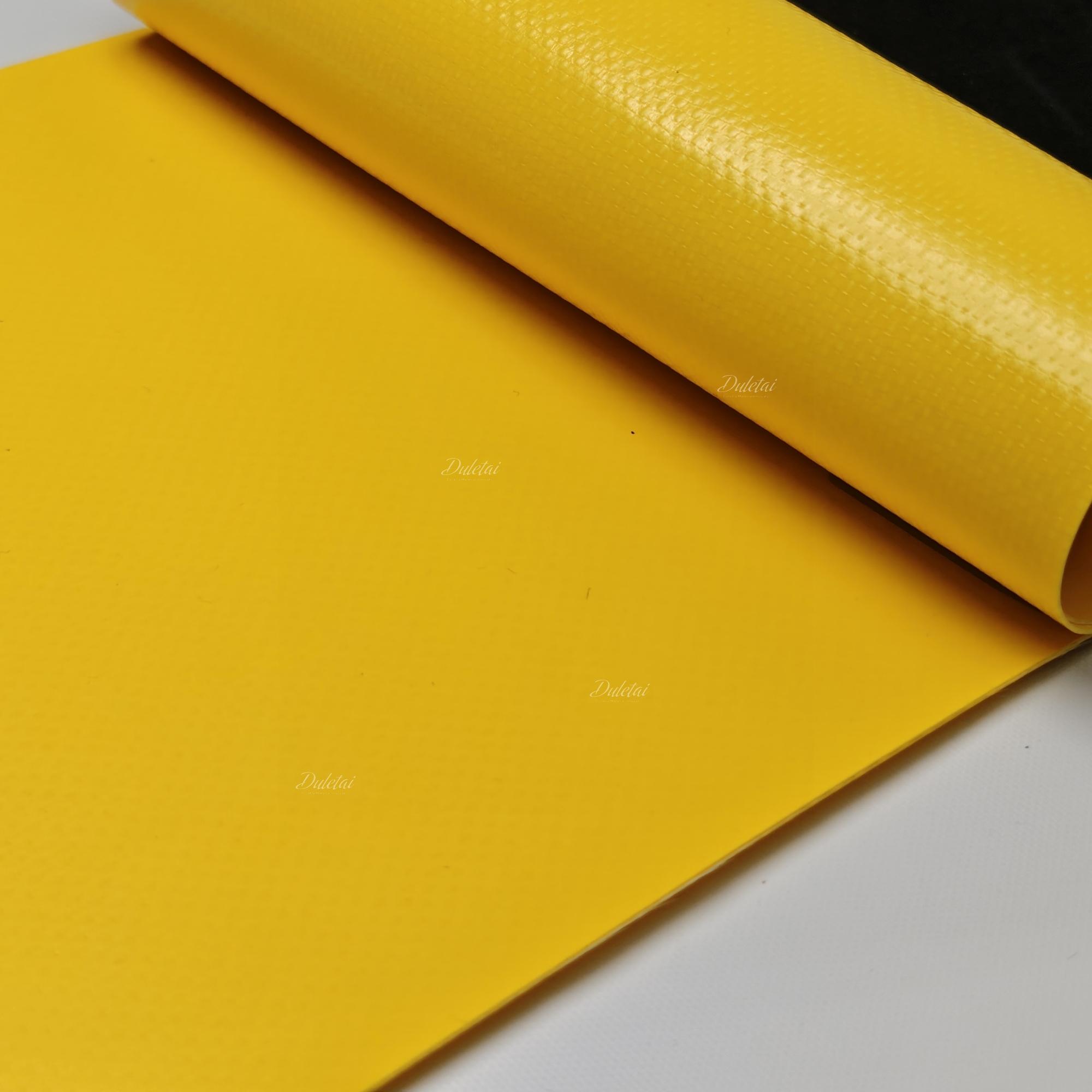

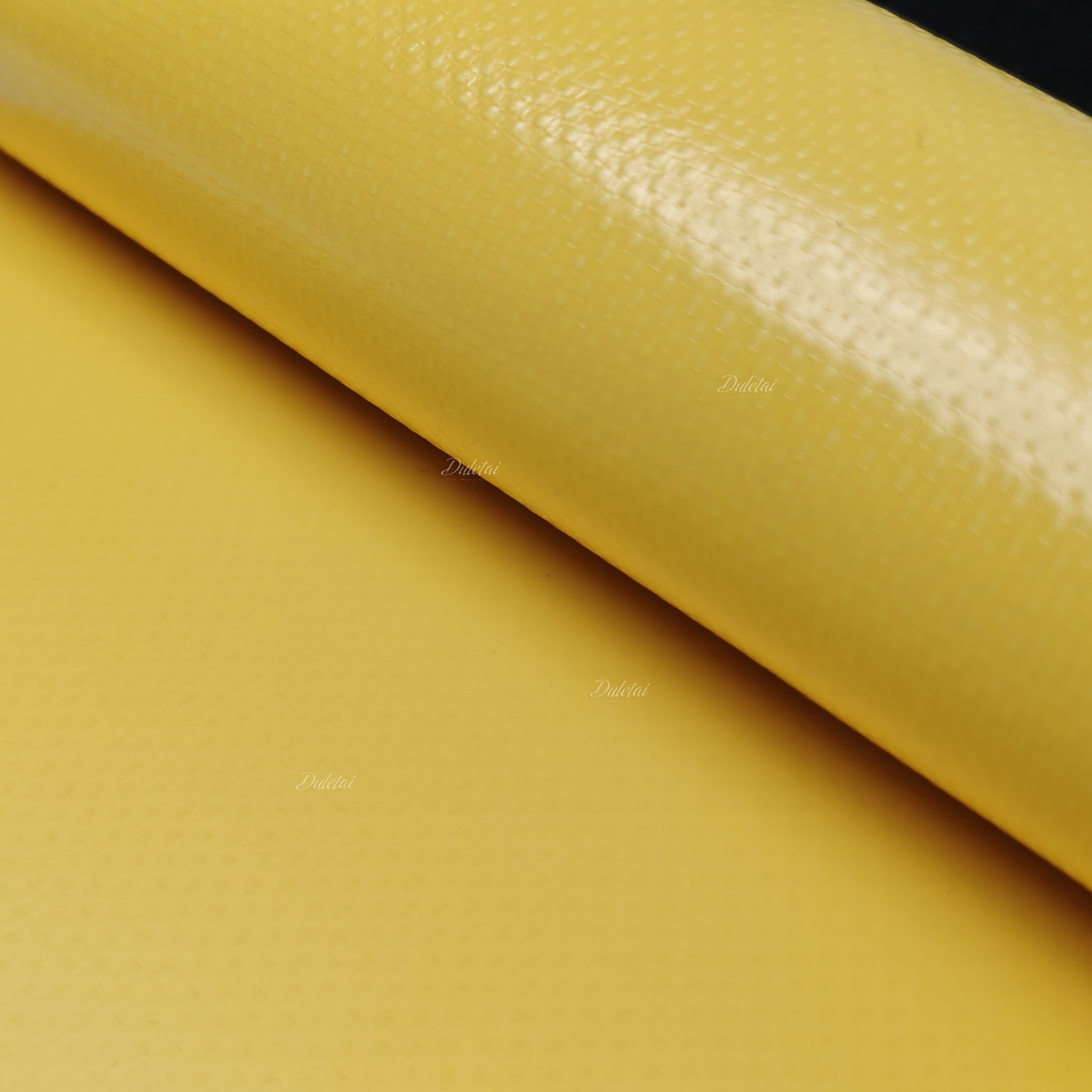

PVC coated air duct fabric is a critical component in modern mining and tunnel construction, providing a versatile and robust solution for air distribution. This specialized fabric is engineered to withstand the challenging conditions found underground, including moisture, chemical exposure, and the constant abrasion against rough surfaces. Designed for durability, PVC coated air duct fabric is typically reinforced with industrial-grade materials of high density 1300D polyester base fabric and 1000gsm material weight that resist tearing and puncturing, ensuring a long service life even in the most demanding environments. The fabric’s inherent flexibility facilitates easy installation and allows for the ductwork to navigate around obstacles within the confined spaces of mines and tunnels.

PVC-coated fabrics have several significant advantages over PVC-laminated fabrics. Firstly, in terms of durability, PVC-coated fabrics often exhibit better performance and a longer lifespan. This is because during the coating process, PVC is bonded with the fabric base material at a molecular level, reducing the likelihood of peeling, wear, and tear. In terms of strength, the coating process also enhances the tensile and tear strength of the foundation since the PVC penetrates the fibers and fortifies the material’s overall structure. Moreover, PVC-coated fabrics provide superior waterproofing capabilities because the comprehensive coating process leaves fewer microscopic gaps for water to penetrate. In chemical resistance, the coating offers excellent protection, effectively defending against chemicals, oils, and other potentially damaging substances. Coated fabrics also perform better in abrasion resistance, as the PVC layer is generally tougher and better integrated with the underlying material. For outdoor applications, PVC-coated materials are often more appropriate, as the coating process can improve resistance to various weather conditions, including UV rays, extreme temperatures, and moisture. Finally, the coating process allows for a range of thicknesses and textures, providing versatility for different applications and finishes. Despite these advantages, PVC-laminated fabrics may be preferred where greater flexibility or cost efficiency is required, as lamination can maintain more of the base fabric’s flexibility and is generally a less costly process. The choice between coated and laminated PVC fabric will depend on the specific requirements of the application.

For regular knife coating machine, 1000gsm heavy-duty pvc fabric need run twice to reach the target weight due to the limitation of the coater , which means the the fabric will be cooked twice in heat case, which potentially degrading its physical properties and life span. Also increasing production costs. Our knife coating machine is specially engineered to that enables it to complete twice coating processes in one pass, This not only preserves the material’s integrity but also optimizes costs while delivering the highest quality. PVC air duct fabric tailored for mining and tunneling applications often incorporates advanced features such as antistatic and flame retardant properties to meet the stringent safety standards required in these hazardous environments. The antistatic feature is essential in preventing the buildup of static electricity within the duct, which can be particularly dangerous in underground settings where the presence of flammable gases or dust could lead to ignition or explosions.

The antistatic property is achieved by integrating conductive materials or coatings that dissipate electrostatic charges safely. Our fabric can meet standard for Antistatic 10^8 ohms. Flame retardant capabilities are equally critical. These are incorporated into the PVC fabric to inhibit the spread of flames should a fire occur. This is done by adding chemical compounds that react to the presence of heat, forming a protective char layer that shields the material underneath and reduces the emission of smoke and toxic gases. With its combination of resilience, flexibility, and lightweight design,

PVC airduct fabric plays a pivotal role in the operational success of mining and tunneling projects, safeguarding workers and equipment while enhancing airflow efficiency. Our comprehensive quality control procedure encompasses checks for fabric weight, surface imperfections, width, roll length, and conducts a series of performance tests, including flame retardant, anti-static properties, tearing strength, tensile strength, and peeling strength. Additionally, we offer expert packaging services, utilizing wooden pallets to guarantee that the product arrives in a pristine and secure condition.

Technical Datasheet:

| Air duct material | DuraTarps DLT-5311 | |

| Structure: | PVC film+Polyester base fabric+PVC film |

| Base fabric: | 1000D |

| Width: | 1.02m-5.0m |

| Weight: | 850g(±10g)/sqm |

| Thickness: | 0.7mm |

| Colour: | Black/Yellow/RAL1018 or customized |

| Flame retardant: | Self-extinguish |

| Tensile strength: | 4400/4060(N/5cm) |

| Tearing strength: | 750/645(N/5cm) |

| Peeling off strength: | 90(N/5cm) |

| Anti-static: | <200 megohm or 1×108Ω |

| Suitable temperature: | -20° to +70° |

| Package: | Paper tube + Craft paper |

| Meter per roll: | 30m-506m |

|

PVC air ducting fabric features:

|

|

| Download Digital Catalogue |