Description

Views: 170

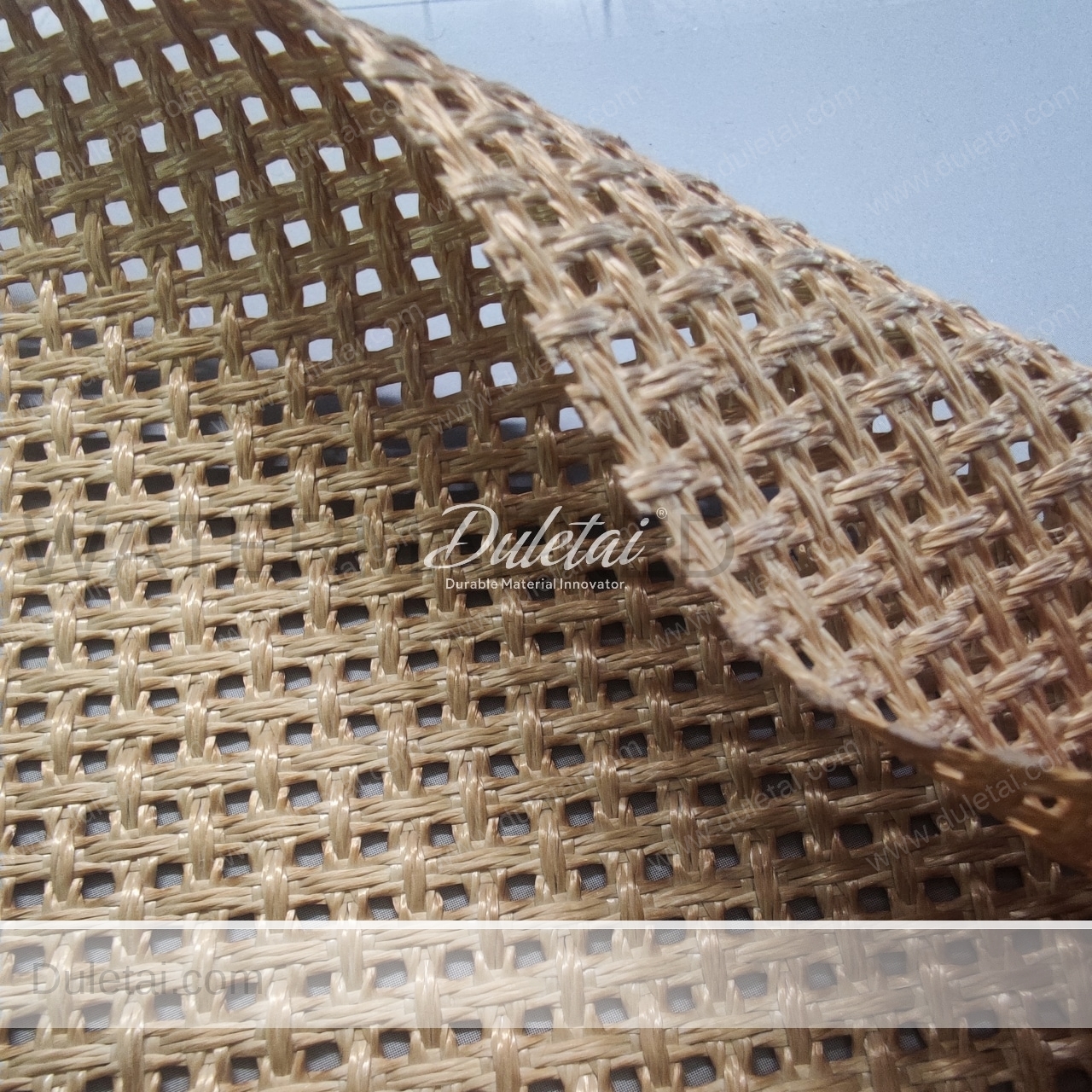

Polytetrafluoroethylene (PTFE) coated fiberglass ventilated fabric mesh is the most durable fabric on the market. PTFE coated fiberglass mesh provides uncompromised and unequaled beauty, longevity, and functionality. PTFE was developed in 1938 and has been used in building applications since the 1970s. PTFE coating is very slick, and nothing sticks to the surface making an ideal surface that is self-cleaning with rainwater.

PTFE coated fiberglass mesh specifications:

| PTFE Fiberglass Mesh | DuraSuntex DLT-PJM4000 | |

| Technology: | Muti layer PTFE (Teflon) coating |

| Base fabric | Fiberglass filaments EC6 |

| Surface: | Matte |

| Colour: | Eeige (Will transform into white colour after completed bleaching ) |

| Weight: | 700gsm |

| Width: | 2-4meter |

| Tensile strength: | 4000 (N/5cm) Warp / 4000 (N/5cm) Weft |

| Tearing strength: | 350 (N/5cm) Warp / 350 (N/5cm) Weft |

| Adhesion: | 60 (N/5cm) |

| Light transmission at 550nm: | 45% |

| Openess: | 25-35% |

| Flame retardent: | A2/A2-s1;d0 |

| Welding methods: | Hot bar welding/FEP welding tape |

| Life span: | 25years |

| Suitable temperature: | -100°F to +450°F (-73°C to +232°C) |

PTFE coated fiberglass mesh features

- Extremely resistant to chemical and biological attack

- Extremely resistant to long-term exposure to weather and UV radiation

- For permanent structures

- High reflectance

- Self-cleaning

- Highest fire resistance

- Limited color possibilities

- Light transmission up to 20 %

- Life expectancy over 25 years

PTFE coated fiberglass mesh applications

- Projects located in extreme weather conditions

- Projects requiring superior fire resistance

- Stadiums

- Exhibition spaces

- Museums

- Transportation hubs

- Leisure

- Retail

- Projects located in tropical, arid or extreme cold climates

- Large, complex structures

- Courtyards

- Atriums

- Structures with an anticipated life of greater than 30 years

- Enclosed structures

- Fabric building facades

- Vertical building facades

- Shading applications

- Permanent facades

- High-rise rooftop decks

- FTS ceilling