Description

Views: 201

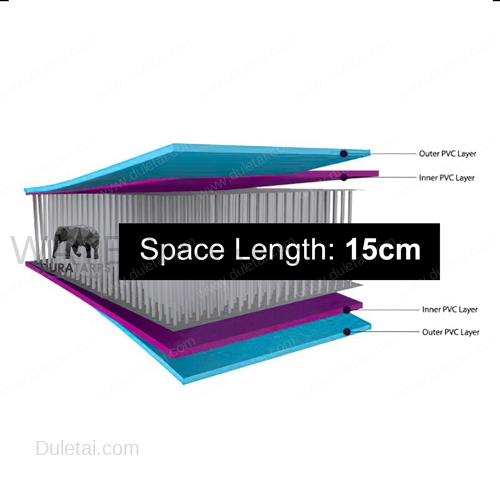

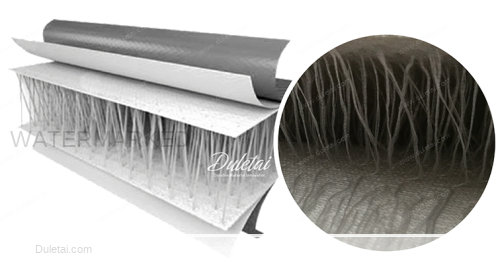

Double wall fabrics are consisted of multi PVC layers with a three-dimensional woven structure; in simple terms, the top and bottom layers were connected by multiple threads that are cross-woven rather than straight, creating 50% more durable warp and weft tensile strength than existing drop stitch technology. 15cm thickness double wall fabric is widly used for stand up paddle boards(SUP).

Double wall fabrics datasheet:

Double wall fabrics datasheet:

| Drop stitch fabric | DuraTarps DLT-6815 | |

| Technology: | High tensile polyester base fabric + Multiple layer PVC Lamination |

| Top and bottom film thickness: | 1.3mm |

| Base fabric: | 500D 16*22 |

| Pattern: | Dot, Wave, In-line |

| Surface: | Matte/Custom print |

| Space Length | 15cm(+/-5%) |

| Weight: | 2700gsm (+/-200) |

| Width: | 1.05-2.06m |

| Tensile Strength (2 Layers) | 4100 x 2800 N/5cm |

| Adhesion Strength (2 Layers) | 150 N/5cm |

| Recommended air pressure: | 15PSI (lbs/inch2) |

| Maximum air pressure: | 30PSI (lbs/inch2) |

| Temperature range: | -50 ~ +70℃ |

| Options: | 6P/16P free, Flame retardent, Anti-fungal, Reach |

| Packing: | Paper tube+PE film+Craft paper |

There is increasing concerns from Europe and US regarding Phthalates. Phthalates refers to Phthalate Esters / PAEs, which are common addictive to soften plastics especially PVC in past 40 years and 80% of Phthalates are used in plastic products. It exists in others include inks, adhesives, sealant agents, paints, film coatings, glass fibers, leather, rainwear, footwear, dyestuff, perfume, softener, polish remover, lubricant, cosmetics and isolation for cables. Phthalates has toxic for reproduction. Based on the application and customer’s safety concerns, there are tests based on different Phthalates. The common testing are 3P, 6P, 7P, 15P and 16P. Our product has passed reach standard, and for higher requirement, we can make 6P/16P.

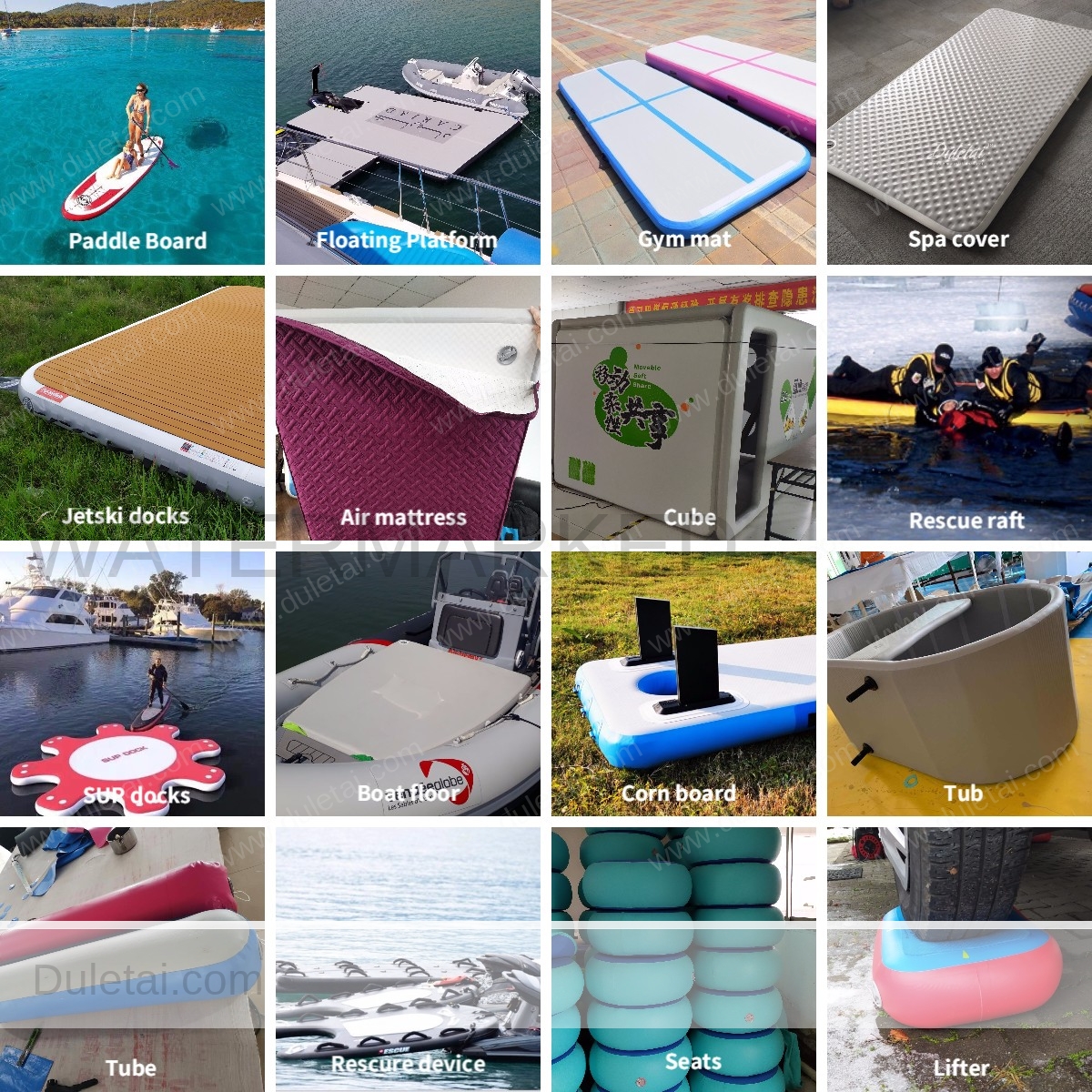

Double wall fabrics applications:

Inflatable boat bottom

Mattress

Inflatable swimming pool

Air deck

Sup board

Air mat

Gymnasium mats

MSL (Monocoque Structural Laminate)

Fusion construction (Pre-laminated dropstitch ) is a sweet spot for balance of weight, rigidity, and cost-effectiveness. The top and bottom sheets of the drop stitch have two layers of fabric that are permanently bonded to each other and a layer of PVC coating on the outside of this double-ply fabric. The resulting board is significantly more rigid and puncture-resistant than a single layer board. The added rigidity of the material allows boards to be made in 5” thickness without having to resort to excessive board thickness for the sake of rigidity. Technically, fusion material also has two fabric layers, but it should be noted that there is a distinct difference between fused material boards (two layers of fabric fused at the raw material stage, with a single coating applied to the outside surfaces) and actual dual layer construction boards, in which a second distinct layer of PVC coated fabric is laminated to the board.

READY MADE PRODUCTS:

Since 2015, we setup a facility with experienced team to make dropstitch OEM products like SUPs , Air mattess, Floating Platforms and all kinds of custom built inflatable products. During these years we have trained a group of professional designers and experienced workers. The whole process from material manufactuering, material cutiing, silk printing , bag sewing and testing are all finished by ourself. So quality is 100% under control. And we can also help a lot customers to upgarde their products with latest technology and material.

More details about custom built projects and dropstitch finished products division please visit:

More details about custom built projects and dropstitch finished products division please visit: