Tent Fabric

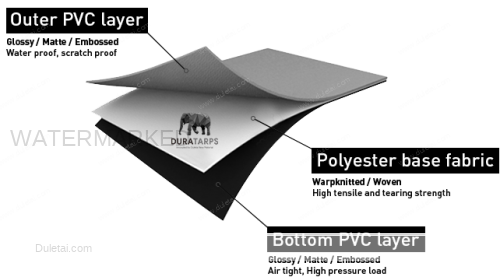

Tent fabric is known as the most popular plastic that is used by many people around the world. We have high quality tent fabric in different colors and pattern. We manufacture our tent fabric and know what makes it a durable piece of pvc material. Most tents namely commercial and large event tents are all made of PVC or Polyvinyl chloride fabric. Larger frame tents and many trailer tents will be made from cotton canvas but will have a heavy Poly Vinyl Chloride (PVC) coating on the roof to make them strong and waterproof. Another important feature is blockout, our material can add extra blockout layer with lamination or coating technology to ensure 100% draking effect. Our heavy duty tent fabric for use in severe conditions suitable for canvas boat tarpaulins and many other outside applications.

|

|

|

PVC tent tarpaulin fabric is a durable and versatile material commonly used for tents, awnings, and outdoor covers. This material offers excellent weather resistance, ensuring it can withstand extreme conditions and tearing, while providing reliable waterproof protection against rain and snow. Additionally, PVC tarpaulin is UV resistant, preventing fading and degradation from sun exposure.

Procurement Recommendations:

It is critical to recognize that even with identical weight (GSM) and base mesh specifications, variations in production processes and chemical formulas can lead to vast differences in price, performance, and lifespan. Choosing the right material based on the specific environment is paramount; ultra-low prices often signal a formula overloaded with calcium powder (fillers) and low-end PVC resins, paired with inferior plasticizers and oils. This significantly compromises the fabric’s weather resistance, folding endurance, and odor profile. As years of fierce market competition have caused a steady decline in average product quality, it is vital to partner with a supplier that prioritizes their brand reputation over short-term price wars.

| Process | Technical Definition | Estimated Lifespan | Professional Verdict |

| Knife Coating | Liquid PVC is spread over the base fabric using a doctor blade. The liquid penetrates the mesh gaps, physically encapsulating the yarns. | 10–15 Years | Superior. The industry standard for permanent structures (warehouses, tensile membranes). Impossible to delaminate. |

| Semi-Coating | A hybrid method. Uses a specialized adhesive layer (glue) between the base fabric and a PVC film, | 4–8 Years | Mid-Tier. Excellent balance for semi-permanent event tents. Stronger bond than standard lamination but lower cost than knife coating. |

| Lamination | (Hot or Cold). Pre-made PVC films are pressed onto the fabric using heat/pressure rollers. The PVC sits on top of the mesh rather than soaking into it. | 1–5 Years | Economy. Suitable only for short-term promotional marquees or banners. Prone to peeling after prolonged UV exposure. |

| Environment | Process | Anti-Wicking | Temp Rating | Recommended Top Coat |

Critical Failure Risk |

| Hot/Humid (Tropical) | Knife Coat | Immersion (High) | -20°C / +70°C | Acrylic/PVDF | Delamination (Hydrolysis) & Mold |

| Freezing (Winter) | Knife Coat | Standard | -40°C / +70°C | Acrylic/PVDF | Cold Cracking (Shattering) |

| Hot/Dry (Desert) | Knife / Semi-Coat | Standard | -20°C / +80°C | PVDF | UV Fading & “Sticky” Surface |

| Temperate (Mild) | Any | Standard | -20°C / +70°C | Acrylic | General Wear & Tear |

| Standard | Scope | Application Advice |

| 3P | Basic Phthalate-free | General industrial tarps. |

| 6P | Low Phthalate | Adult Contact. Standard for event tents and furniture covers. |

| 12P | Ultra-Low Phthalate | Child Contact. Mandatory for schools, play areas, and high-safety zones. |

| BPA Free | Bisphenol-A Free | Potable Water. Mandatory for water storage tanks or food-processing environments. |

PVC Tent Tarpaulins

We can use different combination of polyester yarns and forms of weaving. That will change its tearing strength, breaking strength…etc. And we can adjust thickness and structure of pvc film to control weight, by changing formulation to enable FR, anti-static, air tight, chemical resistant…etc. PVC film hardness can also cause different hand feeling. When producing we can use different technology (for example: cold lamination, hot lamination, knife coating) for different application of material. Different embossing roller can make the material surface glossy, matte or embossed pattern. This is how we customize industrail fabrics according to request. So as an OEM manufacturer, Duletai new material has a large selection of materials in different styles and specifications to chose from or 100% custom built according to customer:

| Item NO. | Weight | Wdith | Thickness |

| DLT-5201 | 420gsm | 1.02-3.20m | 0.32mm |

| DLT-5202 | 500gsm | 1.02-3.20m | 0.43mm |

| DLT-5203 | 550gsm | 1.02-3.20m | 0.48mm |

| DLT-5204 | 650gsm | 1.02-3.20m | 0.51mm |

| DLT-5205 | 680gsm | 1.02-3.20m | 0.52mm |

| DLT-5206 | 700gsm | 1.02-3.20m | 0.59mm |

| DLT-5207 | 850gsm | 1.02-3.20m | 0.65mm |

| DLT-5208 | 900gsm | 1.02-3.20m | 0.75mm |

| DLT-5209 | 1100gsm | 1.02-3.20m | 0.80mm |

Ultra Wide PVC Tent Tarpaulins

5 meter width pvc tarpaulin, the ideal solution for large-scale industrial tents and diverse applications. Unlike standard 3.2-meter tarpaulins, our extra-wide design reduces seams, minimizing leakage risks while enhancing aesthetics and structural integrity. Designed for efficiency, the reduced seams enable faster installation, saving time and labor costs.

| Item NO. | Weight | Wdith | Base fabric | Tensile Strength (DIN53354) |

Tearing Stength (DIN53363) |

Peeling Strength (DIN53357) |

| DLT-5210 | 750gsm | 5.0m | 1000D 23*23 | 3300N/5cm | 400N | 100N |

| DLT-5211 | 850gsm | 5.0m | 1000D 23*23 | 3300N/5cm | 430N | 100N |

| DLT-5212 | 900gsm | 5.0m | 1000D 30*30 | 3700N/5cm | 450N | 140N |

| DLT-5213 | 1000gsm | 5.0m | 1000D 30*30 | 4100N/5cm | 500N | 140N |

| DLT-5214 | 1100gsm | 5.0m | 1000D 30*30 | 4200N/5cm | 550N | 140N |

Click image to view product specifications:

Showing all 12 results