Ventilation

Ventilation duct fabric is our flagship product, backed by decades of OEM production experience, our industrial grade pvc air duct material has been widly used in HVAC systems, mining, tunneling all over the world.

Why choose us for ventilation duct fabric ?

1. Enhanced Anti-Static Performance:

Our material offering a anti-static range upto 1×106Ω. We use a proprietary anti-static PVC formulation. This approach incorporates anti-static agents directly into the PVC raw material, allowing for a slow and consistent release throughout the product’s life span.

2. Fire Resistance & Safety Compliance:

FR level for DIN4102-B1, B2, M1, M2, UL94, NFPA701, EN13501-B1S1d0, all verified test results.

Eenvironmental compliance like REACH and RoHS, Phthalate-Free Options like 3P, 6P, 12P

UV stabilized and mold and mildew resistant.

3. Mechanical Properties:

Our material provides excellent tensile strength, tear resistance and adhesion fastness according to customer’s request.

4. Environmental Resilience:

Designed to withstand harsh conditions, the material exhibits superior wear resistance, weather resistance, and folding resistance. Our laminated material lifespan is 5+years, coated is 10+years. It operates efficiently within a temperature range of -30 to 70 degrees Celsius, making it ideal for both cold and hot air movement.

5. Welding Compatibility:

Designed for exceptional compatibility with High frequency and Heat welding, ensuring long-lasting durability and contributing to the overall performance and longevity of your ventilation systems.

6. Additional Services:

Precision slitting and rewinding services. Our slitter/rewinding machines allow for ultra-narrow slitting from 60” down to 1.1”. Roll lengths reaching up to 500 meters, minimizing interruptions in production and enhancing overall efficiency for end user. Velcro/Zipper stitching service to the slitted material.

We can use different combination of polyester yarns and forms of weaving. That will change its tearing strength, breaking strength…etc. And we can adjust thickness and structure of pvc film to control weight, by changing formulation to enable FR, anti-static, air tight, chemical resistant…etc. PVC film hardness can also cause different hand feeling. When producing we can use different technology (for example: cold lamination, hot lamination, knife coating) for different application of material. Different embossing roller can make the material surface glossy, matte or embossed pattern. This is how we customize industrail fabrics according to request. So as an OEM manufacturer, Duletai new material has a large selection of materials in different styles and specifications to chose from or 100% custom built according to customer:

| Brand | Item NO. | Colour | Weight | Base Fabric |

|

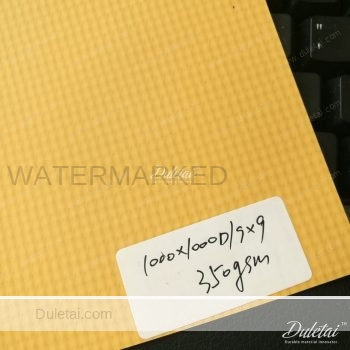

DLT-5301 | Yellow | 350gsm | 1000D 9*9 |

| DLT-5302 | Yellow | 550gsm | 1300*2000D | |

| DLT-5303 | Black | 600gsm | 1000D | |

| DLT-5304 | RAL1018 | 600gsm | 1000D | |

| DLT-5311 | Yellow | 650gsm | 1000D | |

| DLT-5305 | Yellow / Black | 730gsm | 1500D | |

| DLT-5306 | Black | 750gsm | 1500D*2000D | |

| DLT-5307 | Yellow / Black | 790gsm | 1000D | |

| DLT-5312 | Yellow | 850gsm | 1000D | |

| DLT-5310 | Yellow | 1000gsm | 1300D |

Click image to view product specifications:

Showing all 10 results