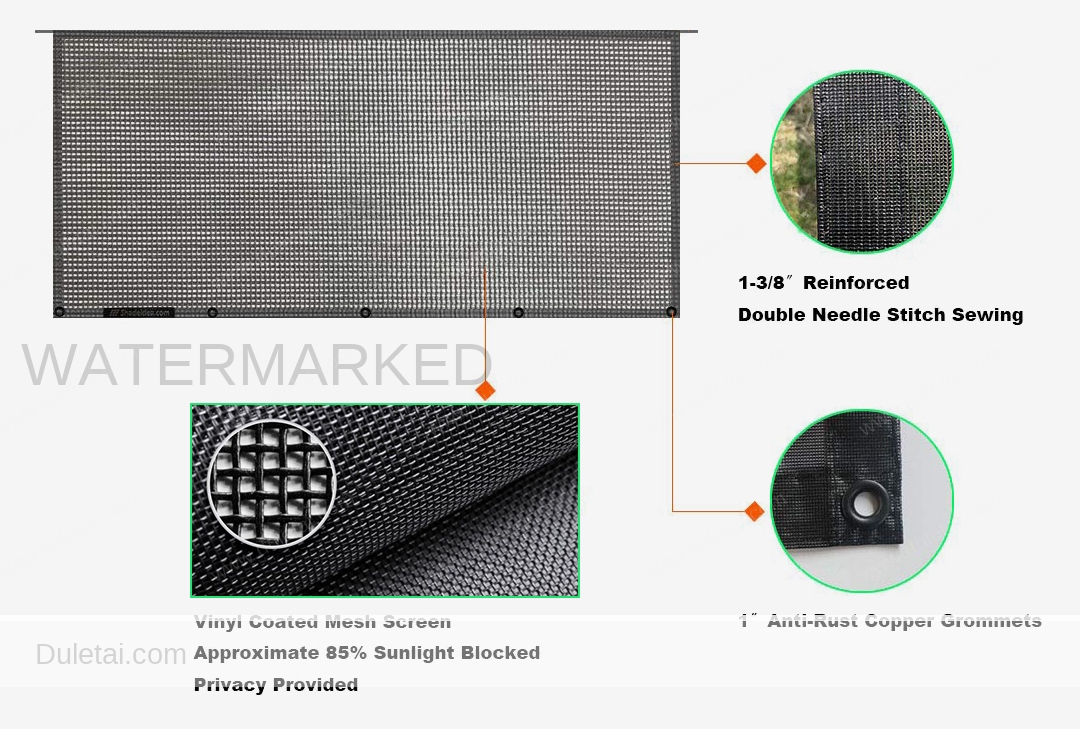

PVC Mesh

PVC coated mesh fabric is one of the most commonly used materials in the world. Available in different weights and strengths, it’s used for everything from tote bags to banners, truck tarps and beyond. The PVC coating means that no moisture can reach the polyester fiber, making it extremely durable and prevents wear from freezing and thawing in cold weather. The strength and dimensional stability of vinyl-coated polyester mesh fabric is determined by a number of factors including the original thickness of the polyester yarn (also known as the denier), the strength (technically referred to as the “tenacity”) of the yarns, and how densely the yarns are woven together (in laymen’s terms, how many yarns per inch). The thicker the yarn and the more yarns per inch, the stronger the final fabric.

We can use different combination of polyester yarns and forms of weaving. That will change its tearing strength, breaking strength…etc. And we can adjust thickness and structure of pvc film to control weight, by changing formulation to enable FR, anti-static, air tight, chemical resistant…etc. PVC film hardness can also cause different hand feeling. When producing we can use different technology (for example: cold lamination, hot lamination, knife coating) for different application of material. Different embossing roller can make the material surface glossy, matte or embossed pattern. This is how we customize industrail fabrics according to request. So as an OEM manufacturer, Duletai new material has a large selection of materials in different styles and specifications to chose from or 100% custom built according to customer:

| Brand | Item NO. | Weight | OZ/SQ.YD |

|

DLT-X series | 240-260gsm | 7.1-7.7oz |

| DLT-XN series | 135-500gsm | 4.0-14.7oz | |

| DLT-BNM series | 130-450gsm | 3.8-13.3oz | |

| DLT-BPM series |

180-350gsm | 5.3-10.3oz |

Click image to view product specifications:

Showing all 4 results