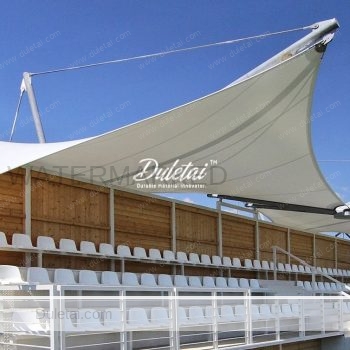

Membrane Structure

Membranestructure made of PVC, or polyvinyl chloride, represent the baseline industry standard for structural fabric construction since the early 1960s. Commonly coated with a protective acrylic or PVDF top coat, this extremely versatile fabric material is fully color printable, carries an expected design life from 10 to 20 years, and is available with inherent light transmission levels ranging from high translucency to total opacity. Due to its lightweight nature and ability to span long distances, PVC membranes offer substantial cost savings versus traditional construction materials. In its natural brilliant white state, this flexible structural fabric significantly reduces net radiant heat retention, making it ideal where cooler interior temperatures are desired all while providing natural daylighting underneath.

There are various types of architectural tensile fabrics with different specifications for tensioned structures. Each material has its own advantages and disadvantages, which determine the best fit for a specific project. As specialists in tensile membrane structures, we assess the overall project requirements before recommending the most suitable fabric and specifications. Below is a detailed comparison table of architectural membrane materials, including lifespan, technical data, and maintenance considerations.

COMPARISON TABLE:

| MATERIAL TYPES |

PVC COATED POLYESTER |

PVC COATED FIBERGLASS |

PTFE COATED FIBERGLASS |

| Lifespan: | 10 – 20 years | 35> years | 35> years |

| Weight | Tensile Strength: | 950gsm | 4200N 1050gsm | 5200N 1350gsm | 7500N |

800gsm | 3500N 1150gsm | 5800N 1550gsm | 7500N |

1000gsm | 5800N 1150gsm | 6600N 1600gsm | 9300N |

| Pricing: | Cost-effective | Approx x2 of PVC | Approx x4 of PVC |

| Flame Retardant DIN4102: | B1 | A2 | A |

REGULAR PRODUCT LINE:

| ITEM#: | Weight | Width | Tensile Strength | Surface Treatment | Customize Options |

Application |

| DLT-6401 | 900gsm | 1.02-3.20m |

4000N | Lacquered PVDF/ Acrylic |

Anti-UV Anti-Mold Anti-wicking Cold-resistant Flame Retardant 10-15 year Lifespan |

Frame structure Membrane structure |

| DLT-6402 | 950gsm | 4000N | ||||

| DLT-6403 | 1000gsm | 4000N | ||||

| DLT-6404 | 1050gsm | 5000N | ||||

| DLT-6405 | 1250gsm | 6000N | ||||

| DLT-6406 | 1350gsm | 7500N |

ADVANCED PRODUCT LINE:

| ITEM#: | Weight | Width | Tensile Strength | Surface treatment | Feature | Application |

| DLT-6421 | 1250gsm | 1.50m |

5500N | Laminated PVF Film / Tio2 |

Extended 20-year Lifespan |

Air-supported structure |

| DLT-6422 | 1300gsm | 6200N | ||||

| DLT-6428 | 1350gsm | 7500N | Laminated PVDF Film / Tio2 |

|||

| DLT-6429 | 1350gsm | 8500N | ||||

| DLT-6433 | 1050gsm | 3.0m |

5000N | Lacquered PVDF |

Enhanced acid and corrosion resistant Chemical gas permeability<2X10-3 |

Sewage tank cover |

| DLT-6434 | 1250gsm | 6000N | ||||

| DLT-6415 | 1350gsm | 8500N | Lacquered PVDF / Tio2 |

Enhanced tearing strength | Tensioned structures | |

| DLT-6416 | 1400gsm | 9000N |

PVDF (Polyvinylidene Fluoride): Excellent self-cleaning,chemical resistance, UV stability, and weatherability.

PVF (Polyvinyl Fluoride): A fluoropolymer with high resistance to UV radiation, weathering, and chemicals.

TiO2 (Titanium Dioxide): Light reflective,enhance UV resistance and reduce environmental impact.

Acrylic: A transparent plastic material with good weather resistance, known for its clarity and color retention.

Anti-wicking: Prevent the absorption of water along the fibers, improving durability and resistance to moisture-related damage.

Click image to view product specifications:

Showing the single result