Tarpaulin tearing strength DIN 53363

Views: 152

Tarpaulin tearing strength by the trouser tear method

1. Scope

This standard specifies a method of determining the tarpaulin tearing strength under specified conditions. It is applicable to products that, because of their flexibility, do not tear when clamped between the grips of a tensile testing machine. The method makes it possible to compare samples of different products provided their thickness does not differ by more than 10%.

2. Normative references

This standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text, and the titles of the publications are listed below. For dated references, subsequent amendments to or revisions of any of these publications apply to this standard only when incorporated in it by amendment or revision. For undated references, the latest edition of the publication referred to applies.

| DIN 51220 | General requirements for materials testing machines, including verification and calibra- tion |

| DIN 53370

DIN 53515 |

Determining plastic film and sheeting thickness by the stylus method

Determination of tear strength of rubber and plastic film by Graves angle testing with cuts |

| DIN EN ISO 291

DIN EN ISO 527-1 |

Plastics – Standard atmospheres for conditioning and testing (ISO 291 : 1997)

Plastics – Determination of tensile properties – Part 1: General principles (ISO 527-1 : 1993 + Corr 1 : 1994) |

| DIN EN ISO 7500-1 | Metallic materials – Verification of static uniaxial testing machines – Part 1: Tension/com- pression testing machines – Verification and calibration of the force-measuring system (ISO 7500-1 : 1999) |

3. Concept

Tear resistance

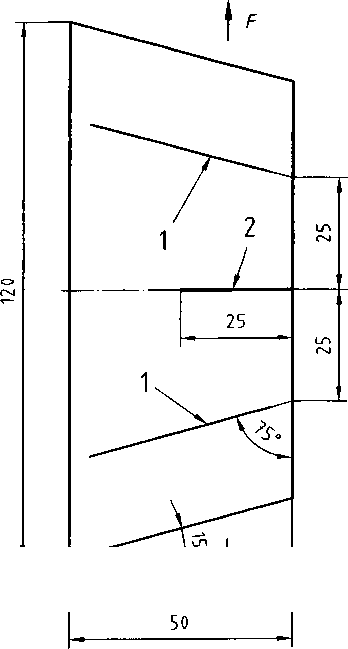

Ratio of the force with which a trapezoidal trouser-shaped specimen as shown in figure 1 resists tear, to the specimen thickness.

Figure 1: Template

Figure 1: Template

Key

- Grip clamping marks

- Incision

4. Specimens

4.1 Sampling and specimen preparation

Specimens as shown in figure 1 shall be cut from the product to be tested. If possible, they shall be taken pap allel and transverse to the manufacturing direction (machine direction) of the film or sheeting so as to permit determination of the tear resistance in both directions as defined by the direction of the incision.

NOTE: If only one piece of the product is available and its manufacturing direction cannot be determined, specimens are to be taken in two directions normal to each other.

The cut directions shall be marked.

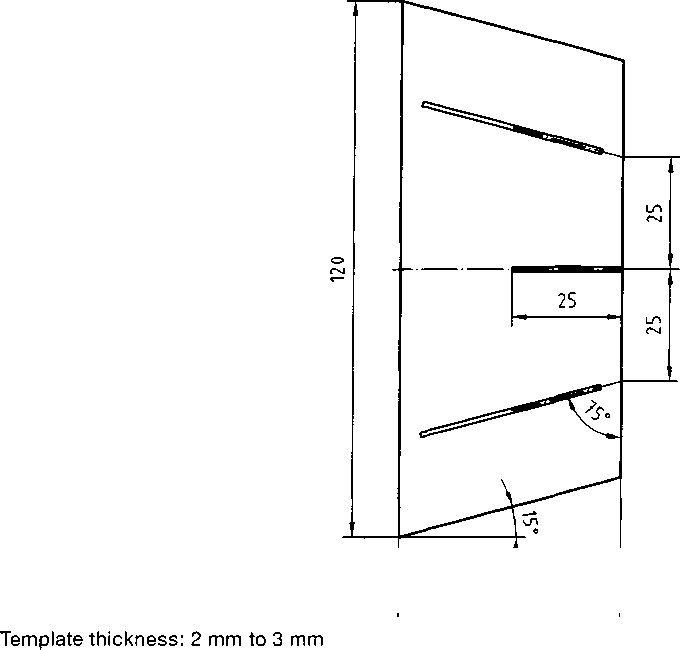

The use of a template as shown in figure 2, made of a cut-resistant material, will make it easier to cut out the specimen and make the incision with a knife or razor blade, and to make the grip clamping marks using a pen cil, ballpoint pen or grease pencil.

Figure 2: Template

4.2 Number of specimens

A minimum of five specimens shall be tested. If specimens are to tested in both directions, at least five shall be taken for each direction. In arbitration cases, at least ten specimens in each direction are to be tested.

5. Apparatus

5.1 Tensile testing machine

Class 1, as in DIN EN ISO 7500-1, conforming to the requirements of DIN 51220 and fitted with a device for gripping the specimen at the marks (see figure 1).

5.2 Measuring device

For measuring the specimen thickness as in DIN 53370.

6. Procedure

Carry out the tear test in a 23/50 standard atmosphere as in DIN EN ISO 291.

NOTE: In many cases, additional tests performed at lower and higher temperatures are recommended. For this purpose, an environmental test chamber shall be used during testing, capable of maintaining the required temperature to within 0.5 °C

- Published in Technology

Roller blind fabric manufacturers

Views: 27

To meet the customers’ over-expected pleasure , now roller blind fabric manufacturers to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Retractable Roller Blind Fabric, Double Roller Blind Zebra Fabric, Black Sunscreen Fabric, Translucent Sunscreen Fabric, We also ensure that your choice is going to be crafted with the highest good quality and dependability. Be sure to feel free of charge to contact us for additional information. We always continually offer you by far the most conscientious customer service, and the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Retractable Roller Blind Fabric, We strive for excellence, constant improvement and innovation, is committed to make us the “customer trust” and the “first choice of engineering machinery accessories brand” suppliers. Choose us, sharing a win-win situation!

Vinyl roller shades fabric is a four-ply fabric consisting of a piece of polyester scrim laminated between three sheets of polyvinyl film (PVC). Scrim is loosely woven material which made out of polyester. As the material is put through the laminator, it is also embossed. An embossing is the surface texture. Duletai’s most common embossings are matte, taffeta, and polish. Our roller blinds fabrics usually have a matte finish for smoothness. The material is rolled onto a cardboard core. Our standard core size is 3”. The polyvinyl chloride (PVC) films were complemented by polyurethane films and coatings. The width of Vinyl roller shades fabric is from 1.02 m up to 3.20m. Color can be customized according to customers’ requirement. We can produce both hot and cold laminated roller shade fabric, for its good flexibility, excellent tensile strength and tear strength and develop all kinds of durable roller shade fabric for different applications.

- Published in Technology

What is coated pvc tarpaulin?

Views: 35

Coated pvc tarpaulin is made from a polyester base fabric that is woven or warpknitted and is coated with a layer of polyvinyl chloride that is available in different types. The polyester based fabric is measured by the weight of thread and the density of the weave. So if the weight is heavier then obviously denier would be too. It is explained as 500D means the thickness of the yarn, 10 X 10 count means there are 10 threads per inch in each direction.. The weight of PVC tarpaulin is usually measured in ounces per square yard. Our common embossing is polished and matte. Surface texture is known as embossing. They are used in a Swimming pool, Bouncing Castle, Truck cover, Ventilation duct, Medical mattress, Boats, Tents, Membrane structure, Ventilation duct and more.

The maximum width of the PVC tarpaulin is 5.1. For smoothness we have a matte finish on products, have a polished finish on our tent products and taffeta finish on hospital products like mattress ticking. Coated pvc tarpaulin is sold by the rolls, we have standard core size which is 3 inch inside diameter but we use 2 inch Core occasionally. Blended rubber coatings, silicone coatings, acrylic coatings, and polyurethane films complement PVC films. All these mentioned films and coatings are strengthened with polyester fabrics and nylon fabric that are non-woven, woven and knits. There are many other varieties of films fabrics and different foils that can be coated or laminated for the different applications or uses. PVC tarpaulin width ranges from 1.0m up to 5.10m m. The color of these tarpaulins is customized according to the requirements of our customers. For good quality, good flexibility, excellent tear strength, excellent tensile strength and durability we produce laminated and coated polyvinyl chloride tarpaulin. We promise to provide quality products to our customers according to the needs of the customers. We deal with the quality products so that our customers get the superb things. Our products are available at affordable rates that the customers can easily buy our products. We have earned a lot of fame due to our services. Our services rely upon quality because quality makes us perfect among all. We use the materials that are reliable and of high level strength. We don’t compromise on the quality of the products and this is the reason we have permanent customers.

- Published in Technology

Fabrics To Meet Various Demands From Different Industries

Views: 31

People who are in the market for good fabrics and are operating on a tight budget, rather than spending cash on used products, should consider contacting Haining Duletai New Material Co., Ltd, and shop for the newly presented fabrics. Those who have not considered something like this or are unaware of what is available in this company may be in for a surprise. This company manufactures and supplies different products that fill many niches such as automotive, agriculture, canopies, medical, military, etc. Of course, clients can still find ones designed for camping, swimming, marketing, and sports. They are the best products available in different materials, designs, sizes, shapes, and colors. And for clients who want personalized items, the company still offers customization services. Customers can order any products according to their specifications and needs. “We use state-of-the-art machinery and employ experienced professionals who design quality fabrics and accelerate the manufacturing process to meet the high demand from customers,” said Alex, CEO of the company.

Green screen fabric is an optimized solution for camera color keying. The green screen creates the stage for an enticing broadcast in seconds. This fabric is a new innovative product widely used by content creators and amateur photographers. Today, many people use social media, and this product is the most suitable for content creators. Makeup artists also use this product to record interviews and more. The fabrics often offer users a large area and full-body effects. Haining Duletai New Material Co., Ltd offers safe, durable, and wrinkle-free products that enable users to capture unique videos and images.

The inflatable gym mat is widely used in sports fields. It provides a comfortable and soft floor on which athletes can train without harshness. For example, it is 5 cm to 20 cm thick and looks like a spring base. The color and size can be customized according to the customer’s requirements, while the weight generally depends on the materials and size. The surface of this product is smooth, very durable, and hardly twisting. Users are recommended to play with pressure.

An inflatable floating platform is a compact size air-filled platform suitable for any outdoor recreational activity. It is generally designed using the latest technology material. Air in the vessel can be filled through multiple chambers using a High volume electric air pump. Similarly, performance is another excellent feature of this platform. It comes in different styles and sizes to suit every need. It can be comfortably used in any situation ranging from Yacht wash-downs, maintenance, and sports recreation. The platform is easy to maneuver since it has an anti-slip EVA deck and uber-toughness.

- Published in Technology