Description

Views: 138

Membrane structure fabric can be used to create an almost unlimited number of unique curved shapes. A tension membrane structure is fabric structures supported by compression or bending elements, like beams, masts, or compression rings. They’re often used as a roof as they are attractive, maintain great natural light, economical and can span large distances. Tension membrane structures transmit more light than traditional structures, reducing and sometimes eliminating the need for artificial lighting during the day. Membrane structure fabric used are reflective, and so can deflect heat, as well as being waterproof and providing shade. Structures can be designed to accommodate blinds around them to fully enclose areas to be used during all weather conditions, all year round. This is great for hotels, restaurants, clubs and pubs. Be it a stadium roof, a marketplace or a bus station cover, or a roof cover for an archeological site, tensile fabrics are used to shelter large structures without using disturbing building elements such as pillars. The excellent strength of the architectural membrane matched by its lightweight and flexibility allow tent structures to withstand heavy loads with minimal use of building material.

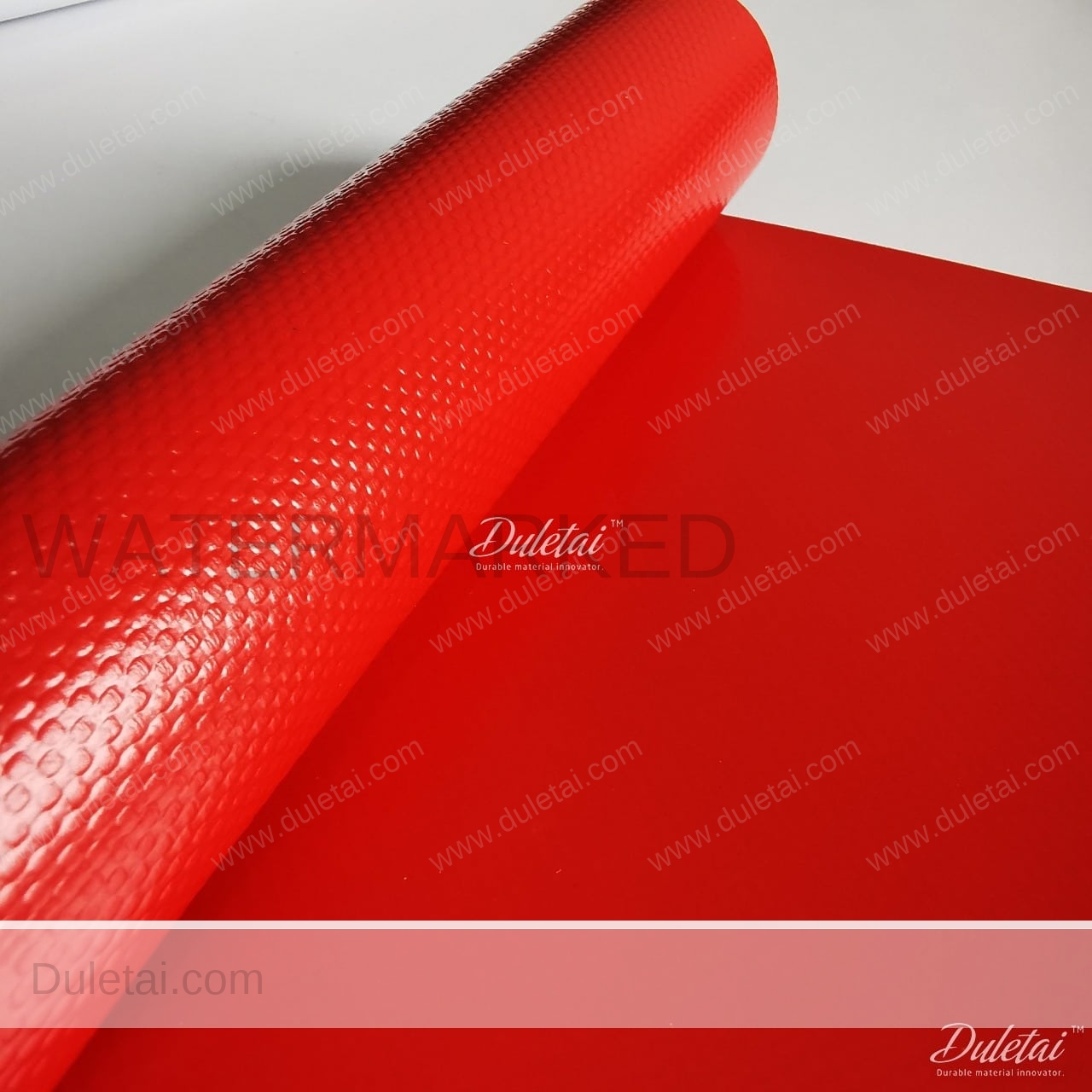

| Membrane structure fabric | DuraTarps DLT-6401 | |

| Technology: | Lamination / Coating |

| Structure: | PVC film+Woven polyester base fabric+PVC film / 3 layers laminated |

| Surface: | Glossy |

| Base fabric | 1000D 20*20 |

| Weight: | 900gsm |

| Width: | 1.05-5.5m |

| Roll length: | 50m |

| Packing: | Paper tube+PE film+Craft paper |

| MOQ: | 1000yards for customization/ 100yards for in-stock |

Membrane structure fabric features:

1. 100% high tenacity polyester yarns with PVC coating;

2. Laminated technology & Hot-melt Coating technology;

3. Good strength, good flexibility and adhesion strength;

4. Outstanding tearing strength for welding;

5. Cold Crack Resistance, Anti-Mildew, Anti-Static treatment, Waterproof;

6. High Strength to prevent any damage during installing.

7. Outdoor life assurance, good weather resistance. (3-5 years)

8. Special treatments adopted to fit into different industry.

9. Special treatment available: Flame Retardant; Anti-Static; Anti-cold; Anti-mildew; 3P Etc.